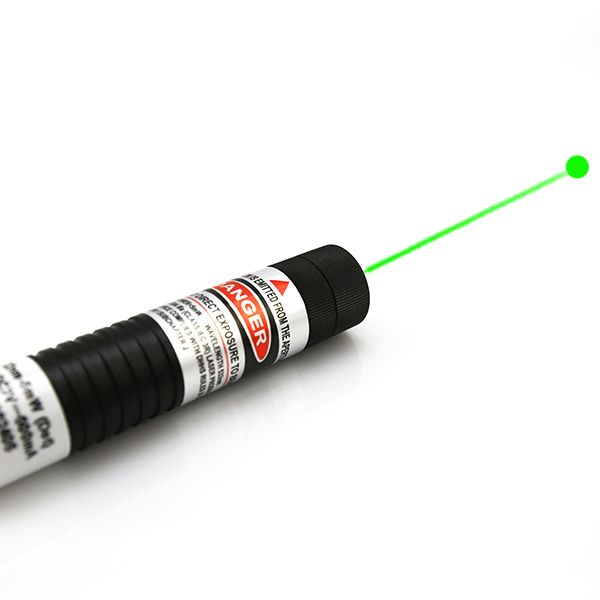

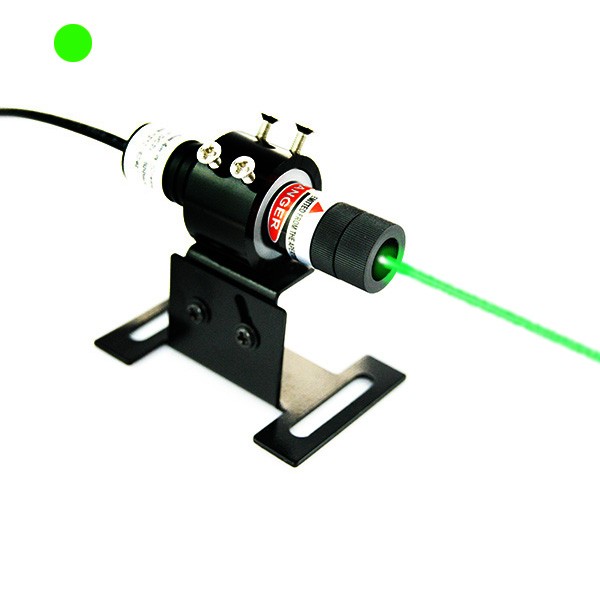

When line indication work is processing for various industrial machinery processing works, on consideration of its high level of accuracy and high brightness line projection, it should be a quite nice solution to operate a high brightness device, such as a 515nm green laser line generator. It gets featured advantages of high fineness and highly straight green reference line projection form its qualified optic lens. In practical line indication work for both of long time and long distance use, once this ultra compact structure made green laser module makes proper installation and adjustment to correct position, it is able to make ultra clear, quick response and high precision green line indication onto multiple working surfaces conveniently:

Line positioning and calibration

Mechanical processing: In lathes, milling machines and other mechanical processing equipment, 515nm green laser line generator provides accurate green line positioning reference for the clamping of tools or workpieces so as to ensure accurate processing positions. It can also be used for station calibration of multi-station processing equipment to ensure the position accuracy between stations.

Electronic manufacturing: In the process of circuit board production, highly straight line is used for cutting and drilling positioning of PCB boards to ensure the accurate installation position of electronic components. In the chip packaging link, it provides accurate positioning reference for the alignment of chips and packaging shells to improve packaging quality.

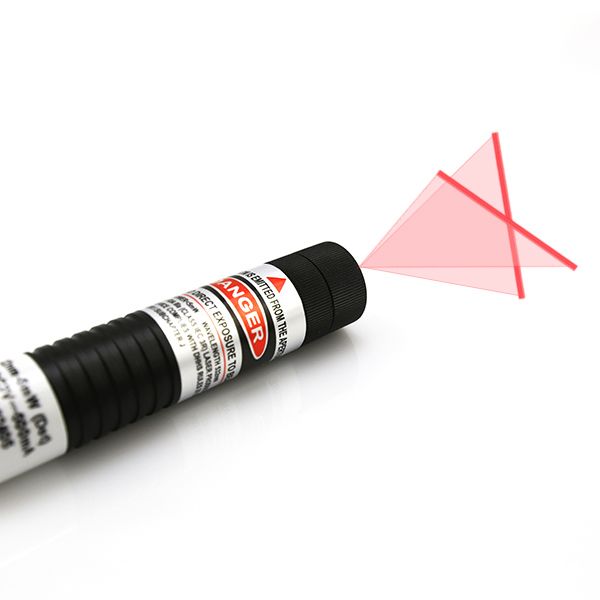

Cutting and welding

Metal cutting: 515nm green laser module provides cutting path line instructions for metal cutting equipment. Operators can accurately control the cutting direction and position according to the laser line, improve cutting accuracy and quality, and reduce material waste.

Welding assistance: In the welding process, green reference line is used for positioning and tracking the weld, so that the welding head can move accurately along the weld to ensure the stability of welding quality, especially suitable for welding of high-reflective metals such as copper.

Measurement and detection

Dimension measurement: In industrial production, 515nm green laser line generator is used to measure the length, width, thickness and other dimensions of objects. By projecting a green laser line onto the surface of an object, using a camera or sensor to capture the image of the laser line, and then calculating the size information of the object through an image processing algorithm.

Surface detection: Detecting defects such as flatness, scratches, and cracks on the surface of metal sheets, pipes, etc. When green laser line is projected onto a defective surface, the laser line will be distorted and deformed. The location and degree of the surface defect can be determined by analyzing the changes in the laser line.

Automated production line

Material transmission and sorting: In an automated production line, 515nm green laser line generator is used to indicate the transmission path and sorting position of the material. When the material passes through the green laser line, the sensor can determine the position and state of the material based on the occlusion of the laser line, and realize automatic transmission and sorting of the material.

Robot guidance: Provide guidance for the motion trajectory of industrial robots. The robot can perform path planning and motion control based on the position and direction of green laser line to achieve precise grasping, assembly and other operations.