In various precise device manufacturing work fields, it is never an easy work for users to get quite clear and accurate enough line instruction on all targeting surfaces effectively. However, once the real line measurement work is processed with quite advanced red line laser alignment, only if it is getting constant electric power source from DC input power supply, it will make prompt line alignment on all working surfaces effectively. When red laser module is getting easy installation and adjustment of red reference line targeting direction, it will easy get no mistake line instruction on desired working surfaces effectively.

Before the use of laser line alignment work, majority of users are using quite simple blocking board, square meter or triangular meter etc, however, it is quite hard to get high efficiency line targeting on desired working surfaces. In order to avoid mistake caused by manual operation, once the real line aligning is processed with a red line laser alignment, after its selection of correct output power and optic lens degree, it will make super accurate and quick line instruction on any targeting surface. The real laser line targeting is also not limited by real work distance, height, corner or others. Noncontact red alignment laser line targeting is able to work at quite long distance, high lighting and other hard reaching places etc, thus becoming a quite popular line measuring tool for all kinds of industrial and high tech work fields etc.

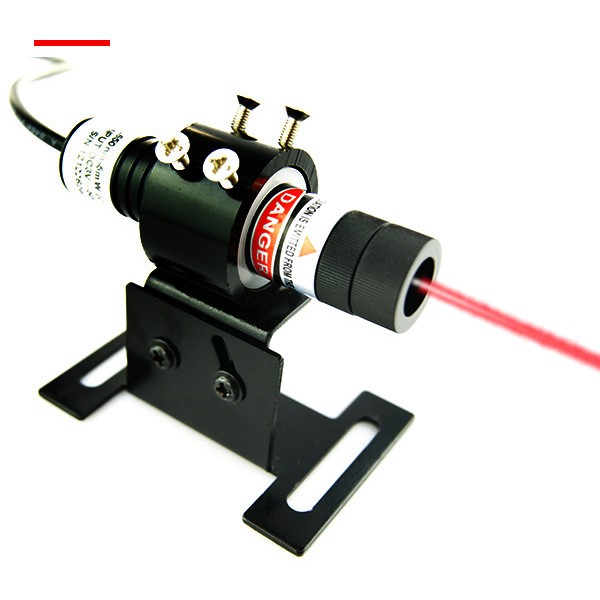

The front part of red line laser alignment is being equipped with glass window, together with internal glass coated lens or separate crystal lens, red line laser alignment is always getting quite high linear quality red reference line on any targeting surfaces. Even though line targeting work is processed under quite harsh working occasion, such as moisture or dust working condition, laser line generator is not affected, but just keeping good laser light cycling use, and achieving extremely stable red laser line targeting in long term use.

According to real working condition, such as work distance, height, and other lighting working occasions, red line laser alignment is getting free selected output power and optic lens degree, and then making sure of clear enough line instruction on all targeting surfaces. Once users are making line targeting with quite high power red laser module up 50mW to 100mW, it will generate super intense laser beam and thermal energy, thus it is a key point to wear proper 650nm wavelength preventing laser safety goggles and avoid eye exposure, and then achieving high security line alignment on all targeting surfaces marvelously.